Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

DeltaQuad Evo Enterprise Edition eVTOL UAV is a limitation-breaking aerial solution for civilian and semi-government use.

DeltaQuad Evo is a fixed-wing eVTOL UAV that has set new standards in the drone world. Longer flight times, extended transmission ranges, and increased payload flexibility are all available in Evo Enterprise Edition. Its advanced features make it ideal for mapping and surveillance missions like infrastructure inspection, precision agriculture, safety monitoring, or light cargo transportation.

Evo Enterprise edition is designed for civilian and semi-government use. It operates based on the DeltaQuad Controller on the world-wide license free 2.4Ghz band and offers radio options up to 30 km range.

This document describes how to set up, operate, and maintain your DeltaQuad Evo series VTOL UAV.

Document status: DRAFT

The vehicle must be operated in accordance with local laws and regulations.

The vehicle may not be operated or flown near or over people, roads, vehicles, buildings, or anything that could result in damage or danger to people or property.

Radio or video transmitters might require special licensing and/or permits.

DeltaQuad or its affiliates can not be held responsible for vehicles that have not been operated or maintained in accordance with the guidelines set forth in this manual, or for behavior resulting from changes made to the vehicle.

This operations manual is provided "As-Is". No rights can be obtained from the contents of this manual.

The original language of this document is English, if this document is read in a translation to any other language, the interpretation of the English version takes precedence.

Software used in conjunction with the vehicle is provided under their respective license and warranty.

The vehicle is provided in accordance with the DeltaQuad Warranty and under the DeltaQuad Terms & Conditions.

The DeltaQuad Evo is not a toy and is not suitable for people under the age of 16.

This chapter covers the basics of the DeltaQuad Evo.

This chapter will discuss how to properly handle the DeltaQuad Semi Solid-State Li-ion battery.

The DeltaQuad Evo is compatible with the DeltaQuad Semi Solid-State Li-ion battery. Using other batteries is not recommended and will impact your warranty.

Use only the DeltaQuad Dual Battery Charger. Do not use a NiCd or NiMH charger - Failure to do so may cause a fire, which may result in personal injury and property damage.

Never charge batteries unattended unless you charge inside a Battery Safe. When charging Li-ion batteries you should always remain in constant observation to monitor the charging process and react to potential problems that may occur.

If at any time you witness a battery starting to balloon or swell up, discontinue the charging process immediately. Disconnect the battery and dispose of it safely. Continuing to charge a battery that has begun to swell will result in fire. Likewise, never use a battery if you find it swollen or ballooned.

Since a delayed chemical reaction can occur, it is best to observe the battery as a safety precaution. Battery observation should occur in a safe area outside of any building or vehicle and away from any combustible material.

Wire lead shorts can cause a fire! If you accidentally short the wires, the battery must be placed in a safe area for observation for approximately 1 hour. Additionally, if a short occurs and contact is made with metal (such as rings on your hand), severe injuries may occur due to the conductibility of electric current.

A battery can still ignite even after 1 hour.

A battery that makes a hissing sound is almost certain to ignite. Consider your own safety and that of your environment before attempting any action

In the event of a crash, after a 15-minute period to ensure the battery was not compromised, you must remove the battery and dispose of it safely.

Before the mission plan can be created, the following steps should be taken to ensure safe execution:

A mission plan should only be executed after a thorough inspection of the entire mission on site. All altitude differences and obstacles should be known and taken into account.

Missions must be allowed to be executed in accordance with local laws and regulations.

The mission path must be free of obstructions for at least 200 meters in each horizontal direction.

During fixed-wing flight (Aerodynamic mode) the vehicle should stay 50m above ground level, near the end of the mission, to reduce landing energy consumed, an altitude of 25m above ground is recommended.

For maximum endurance a takeoff altitude can be set to 25m, however, to ensure the safety systems can function properly, the takeoff altitude should be at a minimum of 60 meters above ground level.

The takeoff and land sites must consist of a level, flat surface that is free of obstructions for at least 5x5 meters.

The takeoff altitude should be set high enough for the vehicle to be able to perform a transition in any direction.

The weather conditions must fall within the maximum allowed conditions.

Both the front and back transition paths must be planned in such a way that the vehicle is pointing with its nose toward the wind while performing the transition.

The intended mission should not consume more than 85% of the total energy available.

At any point in the mission, the vehicle must be able to return to its takeoff point in a straight line at its current altitude.

At any point in the mission, the vehicle must be able to initiate an unscheduled landing without causing damage to itself or its environment.

This section describes how to create an Auterion Suite account.

In order to use Auterion Suite you need to create an account. Ignore the following steps if you already have an Auterion Suite account.

Please follow this link: https://suite.auterion.com/login

Click on Register for an Auterion account.

Follow the given instructions and fill in all necessary information.

Accept the Terms of Service and Privacy Policy by checking the box. Continue by clicking on Create Organization.

Please check your email for an invitation.

Follow the link by clicking on Create account.

Add a name and click on Next.

Choose a password and click on Activate Account.

Log into your account.

You created successfully your Auterion Suite account.

For further documentation about Auterion Suite please follow this link here.

Takeoff in Hover mode and transition to Aerodynamic mode.

Before creating a new mission plan make sure that there are no items such as waypoint commands on the map.

First, enter the Plan view by selecting the Plan tab from the AMC menu.

You can clear all waypoints from AMC and the vehicle by selecting the File Tool from the Plan Tools. Choose the clear option.

When selecting the Start tab the option Add VTOL Takeoff is available.

Click on the map to specify the start location where the vehicle will initiate its takeoff. If the vehicle is currently connected, this location will automatically default to the vehicle's current position.

Adjust the Transition Direction icon displayed on the map. This action determines the transition direction for the vehicle, indicating how it will transition from Hover mode to Aerodynamic mode before proceeding to the next mission item. It is important to set the transition direction against the wind, ensuring that the vehicle is also facing the wind. The default distance between the Start item and the Transition Direction item is set to 70m and can be left at that value.

Set the VTOL Takeoff altitude in the Plan Item Editor. This is the altitude at which the vehicle transitions from Hover mode to Aerodynamic mode.

We recommend a minimum VTOL Takeoff altitude of 60m for all safety features to function properly. Always make sure to set an altitude that surpasses the height of all obstacles present between the Start and Transition Direction waypoints.

In the Initial Mission Settings, the default Waypoints altitude can be set.

This value can be changed for each individual waypoint in the Mission tab. The default value can be set in the application settings of AMC when the is enabled. Settings > General > Plan View

The DeltaQuad Evo and its accessories are stored in a rugged flight case.

1 x Fuselage

2 x Wing

4 x DeltaQuad Evo Semi Solid-State Li-ion battery

DeltaQuad Dual Battery Charger

1x auxiliary battery payload box

1x empty payload box

Ground Control Station (Controller or ruggedized laptop) and accessories

Optional payloads

When removing the fuselage from the flight case you gain access to five extra compartments

Field-proven stabilized cameras for commercial, industrial, and security applications.

This section will discuss how to install, set up, and use all NextVision payloads.

When the DeltaQuad EVO has completed operations it should be switched off, inspected, dismantled, and stored. Flight logs should be retrieved and registered.

Before approaching the vehicle to switch it off note the following;

The vehicle should never be approached when the motors are spinning.

In the unlikely event of a crash, the vehicle should not be approached within 15 minutes. The battery could have been damaged and may ignite.

Always stay clear of the propellers until the vehicle has been powered off by disconnecting the main flight battery.

To switch the vehicle off open the canopy and remove the lid. Then disconnect the main battery connector and remove the battery. The battery should be stored directly and safely.

After a landing, specifically a hard landing or a grass landing, the DeltaQuad EVO should be inspected for damage. Inspecting the vehicle visually at the landing site can help in determining the cause of any problems that might arise in the future. It is recommended, specifically when in doubt or with visible damage, to take pictures of the vehicle before dismantling it.

If there is any dirt on the vehicle or the propellers this should be removed with a damp cloth. Dirt on the wings, fuse, or propellers will significantly impact the performance.

Special care must be taken to inspect the propellers both before and after every flight. If there is any visible or palpable damage to a propeller it should be replaced directly in accordance with the preventative maintenance section.

Dismantle the vehicle in accordance with the assembly section. If you are able to transport and store the vehicle safely with only the wings detached this is recommended as it will reduce the risk of assembly problems.

The DeltaQuad EVO should be transported and stored inside the DeltaQuad EVO Flightcase.

When a sim card is installed inside the UAV, the logs will be uploaded automatically to your Auterion Suite account. Logs can also be manually retrieved through the Analysis section of the Ground Control Station.

In this chapter, we will discuss the DeltaQuad Semi Solid-State Li-ion battery, how to handle it, how to place it inside the DeltaQuad Evo, and how to power up the vehicle.

Auxiliary battery placement

This chapter explains the process for firmware and software updates.

When purchasing a DeltaQuad Evo, operators will be notified via email of relevant firmware updates for your vehicle and software updates for the Ground Control Station (GCS).

To keep the DeltaQuad Evo warranty intact, the firmware update must be performed within two weeks of receiving the email notification.

There are two different updates available.

In this update, the firmware of the DeltaQuad Evo flight controller needs to be updated.

In this update, your DeltaQuad Evo Ground Control Station requires a software update.

If you have questions after receiving the update instructions, please contact our support at [email protected].

1

Controller* and accessories

2

Battery compartment

3

Payload compartment

4

Dual Charger compartment

5

Ruggedized laptop*

This chapter will discuss how to charge and store the DeltaQuad Semi Solid-State Li-ion battery properly.

Power on the DeltaQuad Dual Charger.

Plug the yellow XT90 connector from the power cables of the battery into the charger.

Take the balance lead which is the smaller group of cables with the white connector and plug it into the respective balance port of the charger.

With the DeltaQuad dual charger, you can charge two batteries simultaneously. Therefore make sure to connect the cables of one battery to the same channel.

Per channel, you have two buttons. One for the current and one for the mode.

Set the mode to "Charge" by pressing the mode button.

We recommend charging the DeltaQuad Evo batteries at 15 amperes. You can cycle through the available values by pressing the current button.

Press start.

Your DeltaQuad Evo battery is now charging.

Plug in the power and balance cable of the battery to one of the channels of the charger.

Set the mode to "Storage" by using the mode button.

Press "Start".

If the battery is fully charged when using the storage mode, the charger will discharge the battery to 50% of its capacity. This process can take longer as the discharge power per channel is only 40W.

If the battery is below 50% capacity when using the storage mode, the battery will be charged to 50% capacity at the set current value.

The battery should be stored in a safe and dark location between 5 and 30 degrees Celsius. If the battery has been fully discharged, putting at least some charge (+- 50%) before long-term storage is recommended. This can be done by using the storage mode of the dual charger.

The following section describes how to do a factory reset on the DeltaQuad Evo Controller.

Follow the steps below to reset your controller to its factory settings:

Power on the controller.

Go to the Settings.

Go to System.

Navigate to Reset options.

Choose Erase all data (factory reset).

This process might take a few minutes. After the factory reset, make sure that the controller and all apps work properly. If problems should persist, please contact [email protected].

This section will describe in detail the functionality of every available payload for the DeltaQuad EVO.

The following section describes how to change a DeltaQuad Evo wingtip.

Find a flat surface, such as a table, large enough to accommodate one of the DeltaQuad Evo's wings.

Take a wing of the DeltaQuad Evo out of the flight case.

Position the wing on a table with the wingtip pointing upward to easily access the two screw holes.

Use a Torx tool size 10 (T10) to remove the two screws from the wingtip.

When removing the second screw, the wingtip should begin to loosen from its position where it was secured. Hold and remove the wingtip with the other hand.

Before attaching the new wingtip make sure to use threadlocker on each tip of a screw.

Take the new wingtip and attach it to the wing by aligning the connectors and servo arm with the mounting hole on the side of the elevon.

Tighten both screws. Avoid using excessive force to prevent overtightening and potential damage.

Ensure the wing is properly attached and secured. Test the elevon by carefully moving it upwards. The motor of the wingtip servo should produce a sound and offer slight resistance to the movement.

The wingtip is now installed. Ensure that it is securely aligned and properly set in place. Double-check that all screws are snug but not overtightened to avoid any damage.

If you should encounter problems during the installation process please contact [email protected] for further assistance.

In this section, we cover the steps for assembling and disassembling the DeltaQuad Evo.

For the initial hardware setup, make sure you have ample room to work. Carefully unpack all components from the flight case and inspect them for any damage. If there is damage to your vehicle please document and report this damage to DeltaQuad.

Take the DeltaQuad Evo out of the flight case and place it on a flat surface with the landing gear deployed.

The wing has a big spar close to the leading edge and a smaller spar close to the trailing edge. In front of the big spar is a keying mechanism located in the form of a cuboid.

This keying mechanism prevents mounting the wings on the wrong side.

Slide the carbon spars of the wings into the corresponding blind holes of the fuselage.

When fully locked a clicking sound from the wing lock mechanism must be audible and the wing lock must sit flush with the fuselage.

To disassemble the DeltaQuad Evo, follow the steps for the assembly in reverse order.

Press down the wing lock mechanism with the thumb while the same hand is holding the fuselage in place. With the other hand pull the wing away from the fuselage.

When storing the fuselage inside the flight case, the landing gear must be deployed.

The DeltaQuad Evo comes with 5 propellers, 1 composite "pusher" propeller, and 4 carbon fiber VTOL propellers. The propellers should already be attached when you receive the vehicle. When replacing the propellers please follow these guidelines.

The VTOL propellers consist of 2 Clock Wise (CW) propellers and 2 Counter Clock Wise (CCW).

The bullet-type nut on the propeller adapters is self-tightening, which means they close by turning them in the opposite direction of how the motor/propeller spins. This is done to ensure the propellers do not become detached when the motor spins up. This means that to undo the nut on motors 1 and 2 it turns left, and on motors 3 and 4, it turns right.

The propellers are centered with a small ring inside the mounting hole, this should result in the propeller sitting tightly around the shaft.

Always ensure the centering ring is present and the propeller fits tightly around the shaft.

Mount the propellers in the following positions noting the direction of the propeller as indicated below:

The propellers are attached by removing the motor nut and washer, sliding the propeller on the shaft, sliding the washer on top of the propeller, and fastening the nut.

For the vertical motors (VTOL motors), please make sure to install the washer in the right orientation. The washer has a wider side on top.

After changing the pusher propeller a test flight is necessary to verify that the vibration of the pusher motor is within tolerances. Please contact our support ([email protected]) and share the log file for review.

The DeltaQuad Evo pusher propeller is an APC 15x10E propeller that contains a modified ring to mount properly on the DeltaQuad Evo pusher motor. Please only use DeltaQuad-approved and balanced pusher propellers.

The pusher propeller should be mounted so that the propeller produces thrust towards the rear, this means that the top of the propeller (the side that has the text engraved) should face the motor as shown in the diagram below.

The following section describes the components of the maintenance kit, their installation, and the benefits of using them for optimal performance.

Scheduled Replacement of DeltaQuad Evo Maintenance Kit Components

To maintain the peak performance and reliability of your DeltaQuad Evo, it is crucial to adhere to scheduled maintenance practices, including the replacement of the components from the maintenance kit. Due to the nature of their design and usage, components such as VTOL arms, the pusher motor pod, the wingtips, and propellers incorporate moving parts and utilize lubricants for optimal function.

After approximately 12 months, these components may experience wear and tear, and the lubricants used within them can begin to dry out. This can affect the overall performance and lifespan of the drone if not addressed proactively. Therefore, it is recommended to replace these components with new ones provided in a DeltaQuad Evo maintenance kit.

By replacing these parts at the recommended interval, you ensure that your drone continues to operate at its best, maintaining flight stability, efficiency, and longevity. This proactive approach to maintenance helps mitigate potential issues before they impact your drone's performance during missions.

The DeltaQuad Evo maintenance kit includes the following components:

VTOL Arms

The kit includes four VTOL arms:

Two VTOL arms with clockwise rotating motors and propellers

Two VTOL arms with counter-clockwise rotating motors and propellers

These VTOL arms come pre-assembled with landing gear, ESC (Electronic Speed Controller), motors, and propellers balanced by DeltaQuad to achieve the lowest vibration profile, ensuring smooth and stable flight performance.

Pusher Motor Pod

A fully assembled pusher motor pod is included in the kit. This pod comes with:

A housing for the ESC, motor, and propeller

Pre-installed and balanced for optimal thrust and minimal vibration, the pusher motor pod provides the forward propulsion necessary for fixed-wing flight. It complements the VTOL arms' vertical lift, aiding during both ascent and descent by holding the vehicle's position.

Wingtips

The maintenance kit also contains a pair of interchangeable wingtips. Each wingtip includes:

One servo for precise control of the drone's elevon

One LED for enhanced visibility and status indication

The wingtips are designed to be easily attachable and interchangeable, allowing for quick replacements or repairs. Either wingtip fits on both sides of the drone.

Pre-installed and Balanced Propellers

It is important not to remove the installed propellers, as this would negate their pre-installed and balanced state, designed to achieve the lowest vibration profile.

All propellers in the kit are pre-installed on their respective motors and balanced by DeltaQuad. This balancing process minimizes vibration, crucial for maintaining flight stability and extending the lifespan of both the motors and the drone's structural components.

The DeltaQuad EVO records onboard logs that contain vast amounts of information regarding the flights. These onboard logs will be uploaded to Auterion Suite through Cloud connectivity.

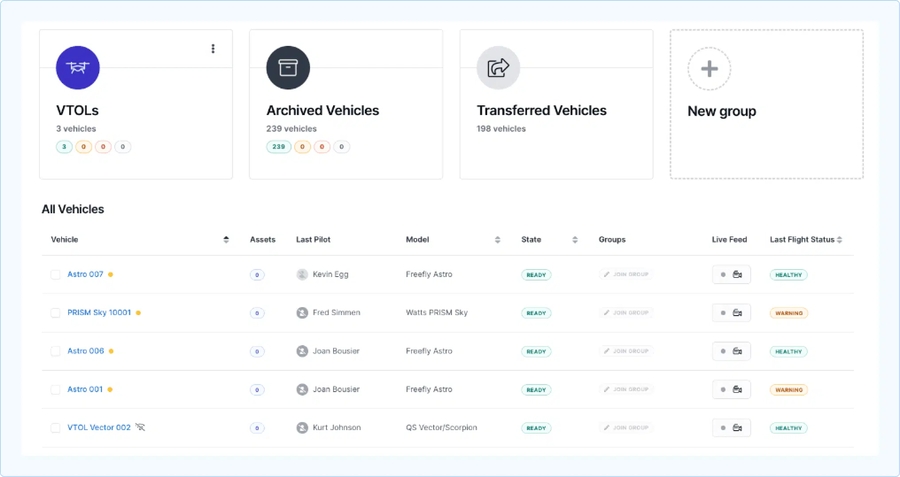

Asset management

Keep track of payloads, parts, and other peripherals, see asset usage per flight, lifecycle state, and proactive measures.

Fleet management

Monitor vehicle overview and status, manage software and app deployment, and log notes to facilitate transparency and collaboration.

As an alternative DeltaQuad recommends the use of AlarisPro. The DeltaQuad EVO is a known vehicle in this system and all components and maintenance schedules are pre-configured.

For other, or self-designed log books the following information should at least be present;

Per vehicle

Serial number

Total flight hours

Last maintenance cycle

Replaced components including the replacement date

Per flight

Vehicle serial number

Date and time

Flight time

Link to the on-board log and/or flight review

Operator

Weather conditions/wind speed

Flight notes, failures, damage, and field replacements

The DeltaQuad EVO has been designed to fly autonomously, this is achieved by planning and executing missions. Missions are set through the Ground Control Station. They can be created and sent to the vehicle directly, loaded from an existing mission plan, or saved to a mission plan. This section covers the basics of planning a mission for the DeltaQuad EVO.

The operator can plan a takeoff and landing from the Fly View by selecting sectors that are free of obstacles at the approach altitude.

The DeltaQuad will take off and transition to aerodynamic mode into a set direction and orbit until new commands are given.

How to take off and land using Fly View will be discussed thoroughly in a later section of this manual.

This chapter gives an overview of the single and dual Custom Payload Kits.

The DeltaQuad Custom Payload system is a versatile and modular solution designed for users who need to integrate custom payloads into the DeltaQuad Evo platform. It offers customizable development kits that include everything required to design, build, and attach payloads to the drone. With available 3D models, users can modify the mounting structure to ensure tool-less integration, making the payload attachment quick and efficient.

Product Variants:

Single Payload: This option provides a compact payload space with dimensions of 225.6 x 103 x 107.5 mm.

Dual Payload: Larger, with two configuration options depending on the number of interface boards (IO), the dual payload provides additional room for custom devices with a size of 225.6 x 207 x 107.5 mm.

Customization Features: Users can further customize the payload plate using the provided CAD files, allowing specific designs to accommodate custom equipment. The provided plates come pre-fitted with mounting holes, making modifications easier.

The following PDF contains all the necessary information for integrating custom payloads into your DeltaQuad Evo. Click to download.

The following section describes how to activate your DeltaQuad Evo.

Activating your vehicle will connect it to Auterion Suite. This will allow you to access cloud features and manage your vehicle remotely.

To activate a vehicle:

Make sure the Evo is powered off.

Connect your vehicle to your computer via USB-C.

Power your vehicle.

Open a browser on your computer and navigate to the vehicle's WebUI:

Click on Activate now or Scan the QR code.

You will be directed to Auterion Suite, where you'll see this pop-up window to activate your Skynode.

Click on Activate and your vehicle will be visible under Fleet Management > Vehicles.

Select a vehicle from the All Vehicles list.

Click on Rename vehicle in the top bar.

Enter the new vehicle name and click on Rename Vehicle.

A vehicle is a collection of parts. An airframe, a Skynode, a flight controller, and more. These various pieces of the vehicle make up the complete "vehicle identity."

To view the serial numbers and IDs of the components associated with a given vehicle, click the "fingerprint" button near the vehicle's name on the Vehicle Page.

This will open up a window that shows all of the IDs of the components that make up the vehicle in the Suite. Each ID controls a specific component. For example, the flight controller ID is how the logs coming out of a flight controller as associated with the vehicle page in the Suite.

This section explains the functionality of the Payload Manager.

The Payload Manager provides an overview of the installed payloads and allows you to edit their settings. It also displays the offset of the main battery in the nose of the vehicle, with the option to adjust the value. Additionally, you can enable or disable the white navigation lights on the Evo's wing tips.

Power up the vehicle and the GCS.

Open the WebUI: after a connection between the Evo and the GCS has been established.

The Payload Manager can be used to verify whether all payloads are registered by the system. Payloads integrated by DeltaQuad are preconfigured and require no additional changes. For Custom Payload Kits, relevant values can be added in the Payload Manager for the respective payload. The nose battery offset is set during production and only needs to be adjusted if hardware in the avionics bay is changed.

The DeltaQuad EVO requires a compass calibration in the following conditions:

When indicated by events described in this manual.

When the telemetry readings are inconsistent with reality.

The DeltaQuad EVO requires a gyro calibration in the following conditions:

When indicated by the UAV

The DeltaQuad EVO requires an accelerometer calibration in the following conditions:

When indicated by the UAV

The DeltaQuad EVO requires a level horizon in the following conditions:

When indicated by the supplier

Sensor calibration is performed in Auterion Mission Control. To access the sensor calibration, you will need to switch the vehicle on and establish a connection between the Ground Control Station and the vehicle. Navigate to the settings view and select the Sensors tab.

QGroundControl will issue a warning about sensor calibration over a WiFi connection. This can safely be ignored by clicking OK.

The following sensor calibrations should be performed:

Compass

Gyroscope

Accelerometer

Level Horizon

All calibrations should be performed with the VTOL modules attached, and any additional payload installed and powered on.

After every calibration step, the autopilot must reboot. The autopilot can be rebooted quickly from the parameters tab under the tools button.

A compass calibration is best performed outside, away from metallic objects, electrical or magnetic interference. To start the compass calibration, click the compass button and follow the instructions on the screen. The calibration process starts when clicking OK. The autopilot orientation parameter in the GCS should remain unchanged. A compass calibration involves rotating the vehicle 3 times over all axis. This calibration step can be performed by hand. The canopy should be closed and the LiPo battery and any additional payload should be inserted and securely fastened.

Perform the calibration as indicated by the images on the ground station. When all axis are finished (images turn green) click OK, leaving the external magnetometer orientation unchanged. Then reboot the vehicle.

After the compass calibration ALWAYS verify the compass is reading correctly by pointing the vehicle north, east, south and west and at every turn verify that the vehicle icon on the ground station is pointing in the correct direction, and remains pointed in that direction for at least 30 seconds. if the compass is not reading correctly by more than 8 degrees, please retry the calibration. If the problem persists please contact Vertical Technologies.

The gyroscope calibration is best performed indoors. It requires the vehicle to sit level based on the VTOL arms. To level the vehicle based on the VTOL arms it is recommended to find a level surface (a table) and place 4 objects of equal height under the quadcopter motors. For example soda cans. The foam underside of the vehicle should be free from the table and the carbon VTOL arms should sit level horizontally.

When the vehicle is sitting level, press OK to start the calibration. This will complete in about 20 seconds. The vehicle should not be touched or moved during the calibration process. Then reboot the vehicle. If, for any reason, the vehicle is moved during the calibration process then repeat the process from the beginning.

To start the accelerometer calibration, click the accelerometer button and follow the instructions on the screen. The calibration process starts when clicking OK. The autopilot orientation parameter in the GCS should remain unchanged. An accelerometer calibration involves positioning the vehicle on all axis. This calibration step can be performed by hand. The canopy should be closed and the LiPo battery should be inserted and securely fastened.

Perform the calibration as indicated by the images on the Ground Control Station, ensuring the vehicle is motionless at each point in the calibration process. Then reboot the vehicle.

WARNING: This calibration is rarely needed outside of the factory. Performing this calibration incorrectly can cause the vehicle to become unstable or crash. Do NOT perform this calibration without consulting your DeltaQuad representative.

Before leveling the horizon all other calibrations, except compass calibration, must have been completed.

The Level Horizon calibration is best performed indoors. It requires the vehicle to sit level on a calibrated flat surface with the landing gear retracted.

When the vehicle is sitting level, press OK to start the calibration.

When operating in high-temperature environments, special attention must be given to the cooling and storage conditions of the DeltaQuad Evo:

Airflow Requirement: If the ambient temperature exceeds 25°C for more than 5 minutes, the DeltaQuad Evo must be placed in an environment with at least 2 m/s airflow to prevent overheating of internal components.

Direct Sunlight Exposure: The aircraft must not be exposed to direct sunlight for more than 5 minutes while idle. Prolonged exposure can cause excessive heating of internal systems. It is best practice to provide shade for the aircraft during pre-flight preparations. During flight, the Evo benefits from sufficient natural airflow to maintain stable operating temperatures, even in direct sunlight.

Storage Conditions: Always store the Evo in a stable ambient temperature environment. Avoid moving the aircraft directly from cold to warm conditions, as this may lead to moisture condensation inside sensitive electronics.

Operations during rain are generally not recommended.

Tolerance: The DeltaQuad Evo is designed to tolerate moderate rain (up to 7 mm/h) while in flight. However, the aircraft must not be launched during active rainfall.

Airspeed Sensor Considerations: Exposure to rain during flight may result in airspeed sensor failure. In such cases, the onboard control system automatically switches to fixed-thrust flight mode, allowing the mission to continue safely. This mode increases power consumption and reduces maneuverability.

Post-Flight Procedure After Rain: If the airspeed sensor is affected by moisture or has failed due to rain, the aircraft may not be relaunched within 24 hours of the incident. Before the next takeoff, the airspeed sensor must be verified to function correctly.

Payload Considerations: ISR payloads may experience reduced visibility or performance degradation when exposed to rainfall.

Operation in cold conditions requires additional caution to prevent icing and control-surface obstruction.

Temperature Range Restriction: The DeltaQuad Evo must not be flown between −5°C and +5°C in the presence of any atmospheric moisture (e.g., fog, drizzle, or light rain). Moisture in this temperature range can freeze instantly on the wings, fuselage, or propellers, leading to loss of lift and thrust.

The DeltaQuad Evo must not be flown in fog, and flight through cloud layers should be minimized. These conditions can lead to unstable flight behavior due to turbulence and may cause moisture accumulation or ice formation on control surfaces.

Takeoff and Landing: The DeltaQuad Evo must not take off directly from snow or wet mud, as these materials can adhere to the landing gear. Once retracted, they may solidify or freeze, potentially preventing proper gear deployment during landing.

Post-Landing Procedure: After operating in snowy or muddy environments, the landing gear must be thoroughly cleaned before subsequent missions.

To keep your DeltaQuad EVO in proper condition the following steps should be taken:

Clean the propellers of any dirt and inspect for damage.

Clean the fuselage and wings, this will improve performance.

Inspect the avionics, and make sure all components are still securely attached in their proper place and all connectors are securely fastened.

To keep your vehicle in the best condition and safe to operate beyond this point scheduled maintenance should be performed. A maintenance kit can be ordered from your DeltaQuad representative.

The DeltaQuad EVO has been designed to allow easy replacement of components. Every component on the DeltaQuad EVO is available as a replacement part.

The maintenance kit includes detailed instructions on all replacement parts.

The following section describes how to change a DeltaQuad Evo VTOL Arm.

Find a flat surface like a table big enough to fit the DeltaQuad Evo's fuselage.

Take the fuselage of the DeltaQuad Evo out of the flight case.

Remove the hatch, as this gives more stability when the fuselage is lying upside down on the table.

Put the fuselage upside down on the table.

To remove the VTOL arm, two screws need to be loosened. To access the screw heads, the landing gear leg must be fully deployed. If the landing gear is retracted, it can be gently deployed manually.

Use a size 2 hex key to loosen the two long screws located under the landing gear leg when it is retracted.

After removing the two screws, the VTOL arm can be detached. Hold the opposite VTOL arm with one hand for stabilization and pull the lower VTOL arm towards you in a straight line. Avoid wiggling from side to side or up and down.

The maintenance kit comes with four VTOL arms: two with clockwise (CW) propeller rotation and two with counter-clockwise (CCW) propeller rotation. Each VTOL arm has an inscription inside its hollow end. The inscription inside the VTOL arm must match the inscription on the respective T-section mount that holds the VTOL arm to the fuselage.

Hold the opposite VTOL arm with one hand for stabilization.

The T-section mount has an alignment groove for the VTOL arm on each side.

Align the VTOL arm so that it catches the alignment groove, then push it forward in a straight line. Avoid wiggling from side to side or up and down.

Push until the VTOL arm is fully aligned and set.

Apply a small amount of threadlocker to the tip of the screw.

Insert and tighten the first screw with moderate force until it is firmly in place. Avoid using excessive force to prevent overtightening and potential damage.

Repeat step 9. and 10. for the second screw.

The VTOL arm is now installed. Ensure that it is securely aligned and properly set in place. Double-check that both screws are snug but not overtightened to avoid any damage. Repeat the process for the remaining VTOL arms if necessary.

If you should encounter problems during the installation process please contact [email protected] for further assistance.

RGB AND THERMAL - Single payload

The Raptor is a lightweight long-range dual EO-IR stabilized camera turret. It features a significant IR range increase and a X80 EO zoom.

ZOOM

X80 (X40 + X2 digital)

FOV

60° WFOV – 1.5° NFOV – 0.75° DFOV

THERMAL RESOLUTION

1280×720

PITCH FOR

-45° to +80°

YAW/ROLL FOR

-180° to +180° Optional 360° Continuous

WEIGHT

850 grams

DIMENSIONS

D-90mm x H-120mm

In this section, we will discuss how to bind the DeltaQuad Controller with the DeltaQuad Evo air unit.

Power on the DeltaQuad Evo and the DeltaQuad Controller. Open Auterion Mission Control. In the upper right corner of the screen, the Radio icon is located. If it has a strike-through and the radio link is not available, a rebinding is required.

Remove the hatch of the avionics bay by loosening the two screws with a Torx tool (T10).

Please use a medium-strength lock bond when tightening the screws again.

In the avionics bay you will see the radio modem. Push the SET button. This puts the modem into the bind mode. When in bind mode, the LED of the modem rotates through different colors.

On the Controller, open the Radio Settings app.

Open WIRELESS PARAMETER CONFIGURATION.

Tap on FREQUENCY MATCHING.

Click on Confirm.

After the binding process has been successful, a connection will be established between the DeltaQuad Evo and the DeltaQuad Controller.

The following section describes how to connect a laptop or Android device to the DeltaQuad Controller.

Requirements:

Auterion Suite account to download the latest AMC version.

An AMC-compatible device such as a Windows, Linux, or macOS computer or Android device.

A hotspot.

A powered DeltaQuad Evo system (UAV + Controller).

Log into your Auterion Suite account on the device of your choice. Select the latest version of AMC and choose your operating system.

Download and run the installer. On Windows, a window might pop up saying Windows protected your PC. Click on More info and Run anyway.

Install AMC by following the instructions.

Power up your DeltaQuad Evo system (UAV and Ground Control Station). Make sure a radio connection has been established.

Create a hotspot on your smartphone. Connect both devices, the DeltaQuad Controller and the computer or tablet, to the hotspot.

On the DeltaQuad Controller, open the Evo Control Panel.

Remember the WiFi: IP address.

On your secondary device, open AMC. Go to the AMC menu in the upper left corner of the screen and open the Comm Links tab. Click on Add in the lower bottom of the screen.

Name the Comm Link. Choose UDP as the Type. The listening port is 14550.

Add a target host which is the WiFi IP address displayed in the Evo Control Panel on the DeltaQuad Controller.

It consists of 4 numbers divided by three dots. At the end of the IP address type a colon and the 5760 which is the port. See the example below.

Click on OK. Choose the Comm Link you want to connect with and click on Connect at the lower part of the screen.

A connection should be established within seconds. Switch to Fly View to see the telemetry and data link.

Power up your DeltaQuad Evo system (UAV and Ground Control Station). Make sure a radio connection has been established.

Connect the secondary device to the DeltaQuad Controller via USB by using the USB-C connection on top of the DeltaQuad Controller.

If not automatically done, USB Tethering must be enabled on the DeltaQuad Controller. You need to navigate to the settings menu (cogwheel).

You can do that by sliding your fingers from the top of the screen downwards. A quick menu will open. Click on the small cogwheel.

Another way to navigate to the settings is by sliding your fingers from the bottom of the screen upwards. A menu with all apps will be displayed. Select the Settings app (cogwheel).

In the settings menu, search for USB and select USB Preferences.

Enable USB tethering.

On the DeltaQuad Controller, open the Evo Control Panel.

Remember the USB: IP address.

On your secondary device, open AMC. Go to the AMC menu in the upper left corner of the screen and open the Comm Links tab. Click on Add in the lower bottom of the screen.

Name the Comm Link. Choose UDP as the Type. The listening port is 14550.

Add a target host, which is the USB IP address displayed in the Evo Control Panel on the DeltaQuad Controller.

It consists of 4 numbers divided by three dots. At the end of the IP address type a colon and the 5760 which is the port. See the example below.

Click on OK. Choose the Comm Link you want to connect with and click on Connect at the lower part of the screen.

A connection should be established within some seconds. Switch to Fly View to see the telemetry and data link.

The following section describes how to change the elevons on the DeltaQuad Evo.

Find a flat surface, such as a table, large enough to accommodate one of the DeltaQuad Evo's wings.

Take a wing of the DeltaQuad Evo out of the flight case.

Position the wing on a table with the wingtip pointing upward to easily access the two screw holes.

Use a Torx tool size 10 (T10) to remove the two screws from the wingtip.

When removing the second screw, the wingtip should begin to loosen from its position where it was secured. Hold and remove the wingtip with the other hand.

With the wingtip removed, the elevon should hang loosely. Hold the leading edge of the wing with one hand. Align the loose elevon with the trailing edge of the wing and move the elevon outward to where the wingtip was installed.

After moving the elevon slightly outward from the wing, pull it toward you. The elevon should come loose.

To install the new elevon, follow the steps described above in reverse order. The elevon hinges have 4 hooks that need to be inserted into the corresponding holes in the wing.

Align the 4 elevon hinges with the 4 holes in the wing.

Lock the elevon hinges by moving the elevon toward the wing base.

Before attaching the new wingtip make sure to use threadlocker on each tip of a screw.

Take the new wingtip and attach it to the wing by aligning the connectors and servo arm with the mounting hole on the side of the elevon.

Tighten both screws. Avoid using excessive force to prevent overtightening and potential damage.

Ensure the wing is properly attached and secured. Test the elevon by carefully moving it upwards. The motor of the wingtip servo should produce a sound and offer slight resistance to the movement.

The wingtip is now installed. Ensure that it is securely aligned and properly set in place. Double-check that all screws are snug but not overtightened to avoid any damage.

If you should encounter problems during the installation process please contact [email protected] for further assistance.

Line of sight (LOS) is a crucial consideration for drone radio systems, as it directly impacts communication reliability and performance.

Line of sight refers to the unobstructed path between two points, such as between a drone and its remote control or between two communication devices. Maintaining a clear line of sight is essential for reliable communication regarding radio systems on drones.

Signal Strength:

Radio signals, including those used for drone communication, travel in straight lines. Any obstacles, like buildings or trees, can weaken or disrupt the signal.

LOS minimizes signal interference, ensuring a strong and stable connection between the drone and the remote control.

Reliability and Stability:

A clear line of sight enhances the reliability of communication. This is particularly crucial for real-time control of drones, where a delay or loss of signal could lead to accidents or loss of the drone.

Range Limitations:

The effective range of radio signals is limited. Maintaining LOS allows the drone to operate within its specified range, ensuring that commands from the remote control reach the drone and vice versa.

Physical Obstacles:

Buildings, hills, and other physical structures can obstruct the line of sight. It's essential to fly the drone in areas with minimal obstructions for optimal communication.

Environmental Conditions:

Weather conditions, such as heavy rain, fog, or snow, can also affect LOS. In adverse weather, LOS may decrease, leading to potential communication issues.

Frequency and Wavelength:

The frequency of the radio signal used by the drone affects its ability to penetrate obstacles. Higher frequencies may have more difficulty passing through obstacles, emphasizing the need for LOS.

The Fresnel zone, in the context of drone radio systems, is a critical concept related to the propagation of radio waves between the transmitter (typically the remote control) and the receiver (the drone). It plays a significant role in ensuring reliable communication by accounting for potential obstacles that might impact the signal's path.

Key points about the Fresnel zone in drone radio systems:

Elliptical Zone:

The Fresnel zone is an elliptical region that surrounds the direct line of sight (LOS) between the transmitter and the receiver. It extends both horizontally and vertically, forming an elongated shape.

Importance for Signal Propagation:

The Fresnel zone is crucial because it represents the area through which radio waves travel as they propagate between the transmitter and the receiver. An obstruction within this zone can cause signal diffraction, leading to signal weakening or disruption.

Factors Influencing Fresnel Zone:

The size of the Fresnel zone depends on several factors, including the distance between the transmitter and receiver, the frequency of the radio signal, and the terrain along the path.

Clearance for Unobstructed Signal:

For optimal signal strength and reliability, it is essential to ensure that the Fresnel zone is relatively free of obstructions. Obstacles within this zone, such as buildings, trees, or hills, can cause signal degradation.

Interference Avoidance:

Understanding the Fresnel zone is crucial for avoiding interference from obstacles and maintaining a robust communication link between the drone and the remote control. Interference can lead to signal loss, reduced control range, and potential safety hazards.

Choose Open Spaces:

Fly drones in open areas with fewer obstructions to ensure a clear line of sight.

Monitor Environmental Conditions:

Be aware of weather conditions that could impact LOS. Avoid flying in heavy rain or foggy weather.

Adhere to local regulations that may require maintaining visual line of sight with the drone. These regulations are often in place to ensure safety and prevent accidents.

In summary, maintaining a clear line of sight is crucial for the effective operation of radio systems on drones. It ensures reliable communication, stable control, and compliance with regulations, contributing to a safer and more efficient drone flight experience.

The following section describes what Auterion Suite is and how to use its services.

Auterion Suite refers to a software platform developed by Auterion.

With every mission, data is automatically transferred into the cloud-based Auterion Suite to provide real-time information captured by the robot while it’s still operating, without any manual intervention.

All flight logs are automatically uploaded for every vehicle and every pilot, and log data are analyzed and available to download as compliance reports.

Auterion Suite enables holistic and scalable fleet management by providing updated information on the vehicle health status, predictive maintenance actions and over-the-air software updates.

Real-time data for quick decision-making

The UAVs can send operational data and live video automatically to the Suite, while they are still in the air, without even pushing a button.

Data and automated workflows

Enable end-to-end automated workflow, from the vehicle operating, over the air to the cloud, and into third-party applications to process the captured data.

Holistic and scalable fleet management

Manage your complete fleet of drones, assets, operators and missions.

Analysis and predictive maintenance

The platform handles software updates, tracks every vehicle for predictive maintenance, and monitors components to flag when you need a replacement.

A vertical takeoff or landing consumes significantly more energy than a fixed-wing flight. For maximum efficiency, an altitude between 25 and 35 meters is recommended for landing.

At every stage in the fixed wing portion of the flight, a vertical separation of at least 25 meters above the highest obstacle must be maintained.

The altitude of the "Planned Home Position" defines the expected touch-down altitude.

The back transition from fixed-wing flight (Aerodynamic mode) to multirotor flight (Hover mode) is performed at the altitude set in the "Orbit point" of the Mission End Action command.

Most wind forecasts are based on ground-level wind. Even 10 meters above the ground the wind can be significantly stronger.

During the transition phase of the "Transition Direction" item, the vehicle has limited navigational abilities and could drift from its intended direction. The transition should therefore always be performed at an altitude where it is safe for the vehicle to perform the transition in any direction.

This section describes how to connect a second screen to your DeltaQuad Controller.

The second screen function can stream the video feed to a local device.

The DeltaQuad Controller provides an RTSP-based video stream. The second screen will connect to the DeltaQuad Controller, not directly to the UAV. This is to prevent the UAV from having to use double the amount of bandwidth.

The video feed displayed on the second screen is the direct video feed from the camera.

If your controller is connected to a 5GHz WiFi network or hotspot, a second device can connect to the same network. For information on how to connect the DeltaQuad Controller to a WiFi network or hotspot, please see the DeltaQuad Controller section.

In order to stream the video feed locally to a second screen you need:

The "IP address" of the DeltaQuad Controller.

VLC Media Player (recommended software) for viewing the video stream on the second screen device. The VLC Media Player is cross-platform compatible and can be installed on many devices.

The DeltaQuad Controller and the second screen device need to be connected to the same Wi-Fi network or hotspot.

In order to ground-test the setup and check the video feed it is necessary to power the DeltaQuad Evo and establish a radio connection between the Evo and the DeltaQuad Controller.

When ground-testing the video feed with an infrared-capable camera it is important to provide active cooling. We recommend a USB fan pointed directly towards the camera.

Once the DeltaQuad Controller is connected to the Wi-Fi network or hotspot you can determine the "Wi-Fi IP address" that was assigned to the DeltaQuad Controller by opening the Evo Control Panel.

Here you will find the Wi-Fi IP address which shows the values for the IP address assigned by the Wi-Fi network or hotspot. The value required is the sequence of 4 numbers separated by a dot, in our example: 192.168.2.68

Make sure that the second screen device is connected to the same Wi-Fi network or hotspot as the DeltaQuad Controller and open the VLC Media Player.

Go to "Media" and open the "Stream..." function.

Go to the "Network" tab.

In the "network URL" field enter the following address:

rtsp://[IP-ADDRESS]:8553/stream1In our example, it is rtsp://192.168.2.68:8553/stream1.

Check "Show more options" and set the value for "Caching" to 100ms. Click on "Stream" in the lower right corner of the window.

Click "Next" in the "Source" window.

Click "Next" in the "Destination Setup" window.

Click "Next" in the "Transcoding Options" window.

Click "Stream" in the "Option Setup" window.

After a few seconds, the video feed should appear in the VLC Media Player.

RGB AND THERMAL - Single payload

The NightHawk2 is an EO/IR stabilized camera with a mere weight of 250 grams. The NightHawk2 delivers powerful thermal observation alongside long-range visible imagery.

The NightHawk2-V is a small-size dual EO-IR stabilized camera turret enabling long-range observation. Implementing technology breakthroughs makes the NightHawk2-V the best camera in its weight class.

NightHawk2-UZ is a dual EO-IR stabilized camera turret crafted for long-range observation applications that demand very low weight. Embodying technology innovations, NightHawk2-UZ provides unmatched capabilities.

ZOOM

X40 (X20+X2 digital)

X40 (X20 + X2 digital)

X40 (X20 + X2 digital)

FOV

60° WFOV – 3° WFOV – 1.5° DFOV

60° WFOV – 3° NFOV – 1.5° DFOV

60° WFOV – 3° NFOV – 1.5° DFOV

THERMAL RESOLUTION

640×480

640×480

1280×720

EO-IR

Single

Dual

Dual

PITCH FOR

-45° to +135°

-45° to +135°

-45° to +135°

YAW/ROLL FOR

-180° to +180°

-180° to +180°

-180° to +180° Optional 360° Continuous

WEIGHT

460 grams

530 grams

560 grams

DIMENSIONS

D-64mm x H-94 mm

D-64mm x H-94mm

D-64mm x H-94mm

All flight characteristics are based on optimized settings at sea level

These values assume 90% battery usage, and low wind conditions and include a low-altitude vertical takeoff and landing at sea level.

* The tolerances are provisional and subject to change

The DeltaQuad Evo Enterprise Edition comes with the DeltaQuad Controller. It provides the communication link between your UAV and the ground systems.

The following section gives a basic overview of the DeltaQuad Controller and its functionality.

The DeltaQuad Controller has three working frequency bands of 800MHz(806-826Mhz), 1.4GHz(1427-1467Mhz), and 2.4GHz(2401.5-2481.5MHZ). It comes with interchangeable antennas to match the frequency band of choice.

To connect your UAV to the DeltaQuad Controller simply switch on the UAV and press and hold the POWER button (5) on the controller for 5 seconds. Once the controller is booted up, the main menu will display.

Before launching your flight control system it is recommended to connect the controller to a mobile hotspot or Wi-Fi network. The controller uses internet connectivity to load satellite maps and for LTE connectivity to the UAV. The DeltaQuad controller must be connected to a 5Ghz mobile hotspot or WiFi network. As one of the primary communication links for the controller is based on 2.4 GHz, these networks will not be displayed. When using a mobile phone hotspot, please configure the hotspot for 5 GHz. Alternatively, you can insert a SIM Card for internet connectivity.

Under NO circumstances attempt to fly the DeltaQuad Evo in Manual Mode! We do not recommend assigning the Manual Mode to any of the switches or reassigning this mode to any of the programmed switches.

The DeltaQuad controller comes with a rich interface offering HDMI, 4G SIM card, USB, Type-C, LAN, Micro SD card, and PPM.

The DeltaQuad Controller can operate continuously for approximately 5 hours. If more operation time is required, the controller can be charged during operation.

To charge the controller, open the rubber cover between the antennas and attach the provided USB charger to the USB-C port. The controller requires high-voltage charging. Standard USB chargers or USB sockets from laptops are not always capable of providing high voltage, but they will extend the battery life of the controller.

To shut down the controller, press and hold the power button until the shutdown menu appears. Select "Power off" to shut down the controller.

The following section describes how to change the DeltaQuad Evo Pusher Motor Pod.

Find a flat surface like a table big enough to fit the DeltaQuad Evo's fuselage.

Take the fuselage of the DeltaQuad Evo out of the flight case.

Remove the hatch.

Put the fuselage on its landing gear on the table.

Remove the two top screws of the avionics bay hatch.

Slightly lift the avionics bay and pull it forward.

On the lower left side of the avionics bay, you will find the gray Pusher Motor Pod connector. Unplug the connector.

There are two top screws and two bottom screws holding the Pusher Motor Pod in place.

First, remove the two bottom screws.

Remove the two top screws while supporting the Pusher Motor Pod with your other hand.

Pull the Pusher Motor Pod slightly towards you and then down, away from the opening. Take the connector of the Pusher Motor Pod and guide the cable through the fuselage opening.

Remove the Pusher Motor Holder (bracket).

The Pusher Motor Holder sits inside the fuselage, securing, and aligning the Pusher Motor Pod. Install the new Pusher Motor Holder (bracket).

The bracket has two mounting points which need to sit in their respective mounting holes and flush with the fuselage.

For the installation of the Pusher Motor Pod, four screws are required: two short screws for the top of the Pusher Motor Pod and two long screws for the bottom.

Ensure to apply threadlocker to the tip of each screw.

To install the new Pusher Motor Pod, guide the cable of the Pusher Motor Pod through the fuselage opening.

Align the front screw holes of the Pusher Motor Pod with those in the fuselage, as well as the screw holes of the Pusher Motor Holder.

Insert and tighten the two short screws at the top of the Pusher Motor Pod.

Insert and tighten the two long screws at the bottom of the Pusher Motor Pod.

Connect the Pusher Motor Pod connectors and store the cable in the lower left corner of the fuselage.

To install the avionics bay hatch, grasp and align the clamps of the avionics bay with the lower edge of the fuselage inside the bay. Follow step 2 in reverse order to achieve this.

Close the avionics bay by tightening the two top screws. Please use threadlocker for these screws.

The Pusher Motor Pod is now installed. Ensure that it is securely aligned and properly set in place. Double-check that all screws are snug but not overtightened to avoid any damage.

If you should encounter problems during the installation process please contact [email protected] for further assistance.

This chapter will discuss the proper placement of the main and the auxiliary battery.

The DeltaQuad Evo has a battery bay (blue), a payload bay (green), and an avionics bay (red).

The main battery needs to be placed on the tray in the battery bay which is located at the front of the fuselage.

The tray has the same form and shape as the underside of the battery.

The battery must be placed in such a way that it fits on the tray.

The thicker power cables must exit the bottom of the battery and lead over the top of the battery toward the XT90 socket of the DeltaQuad Evo.

The main battery must be always installed in the battery bay as explained above. To extend the flight time and the total mission range of the DeltaQuad Evo, in addition to the main battery, the auxiliary battery can be installed in the payload bay.

Never attempt to fly only with the auxiliary battery as this will lead to an incorrect center of gravity. The main battery must always be installed.

Every DeltaQuad Evo comes with an auxiliary battery payload box.

As with the main battery tray the auxiliary battery holder is shaped like the battery bottom plate.

The auxiliary battery must be placed in such a way that it fits on the tray. The thicker power cables must exit the top of the battery and lead over the top of the battery toward the XT90 socket of the DeltaQuad Evo.

There is a latch mechanism on the auxiliary battery holder which secures the battery in place. After the battery is placed the latch needs to be rotated 90 degrees so it is positioned above the battery.

Always install fully charged batteries! Installing two batteries with different voltage levels can cause a fire.

Every payload box displays two arrows on top of each handle.

There are corresponding arrows on the left and right sides of the DeltaQuad Evo's payload bay.

The arrows of the payload boxes must match the arrows in the payload bay.

The payload box orientation is important as its I/O board must align with the respective I/O board of the payload slot.

Slide the payload box into the payload slot.

Push both payload box handles down until you hear a click from the payload box locking mechanism to make sure that the box sits properly in its slot.

The frame of a properly installed payload box sits flush with the frame of the payload bay.

Before takeoff, the payload bay must be fully loaded with either two single payload boxes or one double payload box. If not the LCD above the avionics bay will read one of the following messages:

If payload slot 1 is loaded with, e.g. the Nighthawk 2, payload slot 2 needs to be loaded with the empty payload box which comes with every DeltaQuad Evo.

The DeltaQuad EVO uses Auterion Mission Control (AMC) as its primary Ground Control Station (GCS). The Ground Control Station consists of buttons and has been optimized for use with touchscreen devices.

If you have ordered a Ground Control Station with your DeltaQuad EVO it will have been installed and tested before it was shipped to you.

To install Auterion Mission Control on a separate device such as a laptop or desktop computer, please refer to the . After a successful installation make sure to follow the .

When starting Auterion Mission Control by default the Fly View will be selected.

Auterion Mission Control offers two main views. In the Fly View, you execute and monitor missions. The Plan View is used to plan autonomous missions for your vehicle. Once the mission is planned and uploaded to the DeltaQuad EVO, you switch to the to perform the and execute the mission.

You can switch between the two views by clicking on the Menu Icon .

The application drop-down menu will open. The blue colored tab is the active view. To switch to the other view simply click on the respective tab.

The following two chapters will explain in detail the layout of the and the .

The application menu has four more tabs to choose from.

There are two modes Auterion Mission Control can run in. The Normal mode and the Advanced mode. When tapping five times on the Menu icon a pop-up window will appear with the option to switch to Advanced mode.

When the Advanced mode is enabled the Menu icon is black.

When the Normal mode is enabled the Menu icon is orange.

In Advanced mode, more options are available. For example, the Analyse tab in the Auterion Mission Control menu will become available, or the VTOL Transition distance can only be changed when operating in Advanced mode.

When Advanced mode is enabled tapping five times on the Menu icon will open a pop-up window with the option to switch to Normal mode.

Dimensions:

Wingspan

269 cm

Length

75 cm

Height

33 cm (landing gear extended)

Wing area

84 sq. dm.

Payload bay

20 x 20 x 11 cm

Flightcase dimensions

112 x 82 x 46 cm

Flightcase weight

~ 30.4 kg

Weight and Payload:

Empty weight

4.8 kg

Empty weight including 1 battery

6.8 kg

Maximum takeoff weight

10 kg

Payload capacity

3 kg

Flight Characteristics with Dual battery:

Flight speed

16.54 m/s (60 km/h)

Payload capacity

1 kg

Maximum flight time

272 minutes (4 hours 32 minutes)

Range through air

270 km (168 mi)

Power

Battery type

Semi Solid State Lithium-ion

Battery cells

6

Battery capacity

22Ah per battery

Tolerances *

Maximum takeoff/landing wind

12.5 m/s (45 Km/h)

Maximum wind cruise flight

14 m/s (50 Km/h)

Maximum precipitation

7mm/h (Drizzle)

Operating temperature

Between -20 and +45 Celsius

Maximum flight altitude AMSL

13.000ft (4000m)

Number

Type

Function

1

3 position switch

FLIGHT MODE

UP: Altitude flight mode

CENTER: Altitude flight mode

DOWN: Mission flight mode

2

Right joystick

In hover mode

Stick up: move forward

Stick down: move backward

Stick left: move left

Stick right: move right

In fixed-wing mode

Stick up: descend (nose down)

Stick down: climb (nose up)

Stick left: bank left

Stick right: bank right

3

Joystick

Gimbal zoom

4

Push button

Return to Land

NOTE: RTL must be deactivated before the vehicle will accept any other commands.

5

Push button

POWER

Press and hold for 5 seconds: power on/off

Press: screen on/off

6

Left joystick

In hover mode

Stick up: climb

Stick down: descend

Stick left: yaw left

Stick right: yaw right

In fixed-wing mode

Stick up: gimbal up

Stick down: gimbal down

Stick left: gimbal left

Stick right: gimbal right

Number

Interface

6

HDMI*

7

4G SIM card slot

8

USB

9

Type-C

10

LAN (RJ45)

11

Micro SD card slot

12

PPM

Vehicle Setup

Vehicle configuration, including sensor calibration and safety actions.

Photos

View photos and videos downloaded from the vehicle.

User Acount

Login or logout of Auterion account. This associates pilots with flights on Auterion Suite.

Settings

Application Settings

The last action of the mission plan. Execute a landing pattern or loiter.

After the waypoints have been placed the Mission End Action has to be planned. When clicking on the End tab within the Plan Item Selector two options are available.

When selecting Add Land Pattern a window will appear with the request to choose a location on the map.

The designated location will be the position of the Land item . AMC will automatically plan an Orbit where the DeltaQuad EVO will descend to the set altitude, approach the Land item, transition to Hover Mode, and land at the designated location.

If the Ground Control Station is connected to the DeltaQuad EVO or the simulator you get a second option to set the Land item to the vehicle location.

After the Land Pattern is positioned several options will be available in the Mission End Action tab on the right side of the screen.

Altitude - The altitude at which the aircraft transitions from Aerodynamic mode to Hover mode prior to landing. The altitude is relative to the launch altitude.

Radius - The radius of the descent circle. The aircraft will descend in Aerodynamic mode from the mission altitude to the specified altitude mentioned in the Altitude setting above.

The DeltaQuad EVO will orbit clockwise when the Orbit clockwise box is checked.

Disable that option to orbit counter-clockwise. This will change the location of the Orbit.

Heading - When placing the Land Pattern it automatically positions the Orbit and Land items in the same direction as the Start and Transition Direction items. As the DeltaQuad EVO needs to launch and transition into the wind it also needs to do the final approach and landing facing into the wind.

The heading can be changed by dragging the Land Pattern items on the map or using the Heading slider.

Altitude - The altitude of the Landing point is the relative altitude to the Start item where the vehicle is expected to touch down. When landing at the same altitude where the takeoff occurred this can be left at 0. The aircraft will confirm the setting by utilizing its integrated ground distance sensor.

Landing Dist - The distance between the Orbit and the Land item will be automatically set to 50m. You can change this distance by dragging the Land item on the map or by using the slider. Values between 50m and 200m are available.

At the bottom of the Mission tab, you can edit the position of the mission item, or delete it.

When choosing Add Loiter from the Mission End Action tab an Orbit waypoint will be placed on the map.

The Waypoint type and other settings can be adjusted as explained in the chapter Set intermediate waypoints.

This section covers the flight controller's safety features. To access the safety features configuration screen you will need to switch the vehicle on and establish a connection between the Ground Control Station and the vehicle.

To modify the parameters click on the Menu Icon in the upper left corner of Auterion Mission Control. A drop-down menu will open. Click on the Vehicle Setup tab.

A new drop-down menu will appear. Click on the Safety tab.

Now you have access to all safety settings.

Default: Return at critical level, land at emergency level

Default Warn level: 10%

Default Failsafe level: 7%

Default Emergency level: 5%

These parameters define what the vehicle does when reaching low battery levels.

Note: The levels are those estimated to be reached when having flown to the landing site. This means that the further the vehicle is from its intended landing location, the sooner these actions will be taken. The vehicle will attempt to maintain these values when landed.

Warn level: The percentage where the vehicle will give a visible and audible warning to the Ground Control Station

Failsafe level: The level at which the vehicle initiates the critical battery action. (return)

Emergency level: The level at which the vehicle initiates the emergency battery action. (land)

Default Failsafe Action: Return mode

RC Loss Timeout: 5.0s

Set the action on RC loss, and how quickly the vehicle responds.

This setting defines the behavior when the Radio Control (RC) Link is lost. The RC Link refers to the communication connection between the DeltaQuad Controller (transmitter) and the DeltaQuad Evo.

The DeltaQuad Controller will have both RC and Data Link functionality. It is recommended that you leave this setting as is.

When flying in Altitude mode (manual control), and the connection with the vehicle is lost, the system will initiate the Return mode after 5 seconds regardless of the settings in the Data Link Loss Failsafe Trigger.

Default: Disabled

Default timeout: 100s

This controls the behavior of the vehicle when the telemetry link is lost. When flying fully autonomous missions where the loss of telemetry is allowed or expected, this parameter should be set to Disabled.

Some local laws require this value to be set to Return mode.

The Settings of the Data Link Loss Failsafe Trigger should be checked before pausing the vehicle mid-flight. If the trigger is disabled and the Data Link is lost after the vehicle is paused and in Hold mode, the pilot has no possibility of giving a new pilot command. Until the Data Link is regained, the DeltaQuad EVO will remain in Hold mode. If the Data Link can't be re-established, the vehicle will remain in Hold mode until the Low Battery Failsafe Trigger will be activated.

Default action: Warning

Default max radius: Disabled

Default max altitude: Disabled

The geofence failsafe trigger can be set to limit the vehicle's radius and/or altitude. When settings these parameters the vehicle will perform the defined action upon breaching any of these.

Default climb: 60m

Default home action: Land immediately

These settings define how the vehicle behaves when it engages the Return to Land function. The Climb altitude is the minimum altitude relative to home the vehicle will maintain for its return path.

If the altitude of the DeltaQuad EVO is lower than the Default climb value, in this case, 60 meters, the UAV will ascend to that Default climb altitude of 60 meters.

If the vehicle is higher at the point where the Return to Land is triggered it will maintain that altitude to return.

The DeltaQuad EVO can perform an autonomous Return to Land when instructed from the Ground Control Station, when instructed from a mission, or when triggered by a failsafe event.

If the DeltaQuad EVO is in Fixed-wing mode when the Return to Land event is triggered the UAV will make use of the Landing Pattern from the planned mission.

The DeltaQuad EVO will return in Fixed-wing mode to the Loiter waypoint of the Landing pattern in a straight line at the altitude the UAV is at when the RTL was initiated.

If the altitude of the DeltaQuad EVO is higher than the Default climb value the UAV will stay at its altitude and return to the Loiter Waypoint.

When reaching the "Loiter" waypoint the DeltaQuad EVO will loiter and descend to the set Approach Altitude. In the final approach towards the Land item, the DeltaQuad will perform a transition to Multirotor mode and land as planned in the mission.

Be aware that if your planned Land item is not at the same location as your Launch item, the DeltaQuad EVO will land in a different location rather than your Home Position.

If the DeltaQuad EVO is in Multirotor mode when the Return To Land event is triggered the UAV will return to the Land item in a straight line at the altitude it is at when the RTL was initiated.

Because the DeltaQuad EVO is in Multirotor mode it will not make use of the Loiter waypoint and the Landing Pattern but head directly for the Land item.

If the altitude of the DeltaQuad EVO is lower than the Default climb value (60m) the UAV will ascend to that Default climb altitude (60m) whilst heading for the Landing item.

If the altitude of the DeltaQuad EVO is higher than the Default climb value the UAV will stay at its altitude and return to the Landing Pattern.

When reaching the Land item the DeltaQuad EVO will descend in Multirotor mode and touchdown at the Land location.

Be aware that if your planned Land item is not at the same location as your Launch item, the DeltaQuad EVO will land in a different location rather than your home location.

Default Descent Rate: 1,2m/s

Disarm after: 2s

This controls the landing behavior. The default descent rate is the maximum speed the DeltaQuad EVO descends in Multirotor during a landing.

In windy conditions, the vehicle will correct itself by applying a lower descent rate and the indicated descent rate might not be achieved. The DeltaQuad will brake and slow down its descent from approximately 8 meters above the Home Position to guarantee a soft landing.

The default value of the Descent Rate can be left at 1,2m/s. Nevertheless, if it needs to be changed it should not be increased above 1.5m/s.